Carbon Fiber Manufacturing

Dexcraft is a leading manufacturing company and supplier of top quality carbon fibre elements. We have expertise in series production (minimum 20 items) of carbon fibre elements.

We manufacture items in bulk using materials that include epoxy composites with carbon /aramid filaments. We take every effort to ensure top quality workmanship & the highest aesthetics when manufacturing our products.

Here are just a few projects that we've worked on:

Carbon Fiber Parts Manufacturing and Fabrication

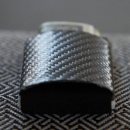

Carbon fiber has a leading position in the market for manufacturing composite materials. The laminate features light weight, strength and a unique luxurious appearance.

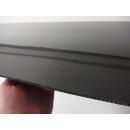

We manufacture and supply carbon fiber components and products. Our offer includes formed carbon fiber parts as well as carbon fiber sheets.

All carbon fiber parts and products are manufactured with high quality epoxy resins. We use a curing oven or autoclave for manufacture of products resistant to high temperatures. We can manufacture products according to your specific quality and strength parameters.

We supply carbon fibre components to different markets including Switzerland, Germany, Italy, USA, United Kingdom, Finland, Spain, Poland and many more.

We are capable of supplying any product using CNC machinery and 3D design. We manufacture the product identical to the 3D model or sample part provided.

Carbon fibre products technology

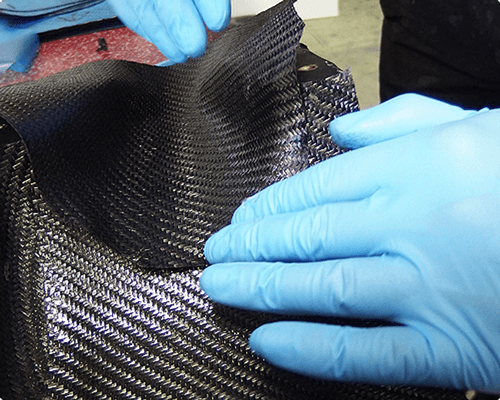

Thanks to over 15 years experience and know-how, we have implemented advanced production methods to meet client individual needs and requirements:

- Pre-preg in autoclave: to provide ultra-light weight components that offer excellent aesthetic appearance. Pre-preg carbon fiber molding has applications in Formula One racing, amongst others.

- Resin infusion technique: perfect for large items of moderately complicated design including table tops, casings, covers, sheets.

- Manual laminating: carbon fiber molding method used for small products of simple design where cost-effectiveness is crucial.

We apply the best techniques that ensure high quality end products as well as modern design. We provide top quality services and products thanks to our expertise, highly skilled specialists, modern facilities and strong motivation to always give exceptional customer satisfaction.

Why Dexcraft?

- Over 15 years experience and 100 implemented projects.

- Carbon fiber products series production (min. 20 items).

- Products of premium quality and unique aesthetics.

- Long-term cooperation with partners among others in Switzerland, Germany, United Kingdom, Belgium, Spain, USA, Poland.

- Advanced facilities: autoclave generating working pressure 8 bar, clean room, paint shop, 4 axis CNC, oven (2x2x2m, temp. 250 C).

- We can supply products that carry a logo and serial number.

- Timely delivery and competitive prices.

Project execution- 10 steps:

- Consultation: defining the objectives.

- Designing: from an idea to 3D design.

- Mold and model: with focus on precision and attention to detail.

- Prototype: demonstration of first product iteration for client’s approval - molding the first carbon fiber product.

- Series production: production according to individual requirements regarding quality and quantity.

- Treatment: cutting, milling, drilling holes.

- Assembly: assembly with adhesives, bolts, rivets.

- Finishing: painting, marking, polishing

- Quality control: measurements, precise visual inspection.

- Logistics: packing and shipping.

DEXCRAFT - supplier of comprehensive carbon fiber solutions.

We implemented over 100 carbon fiber parts projects. We supply:

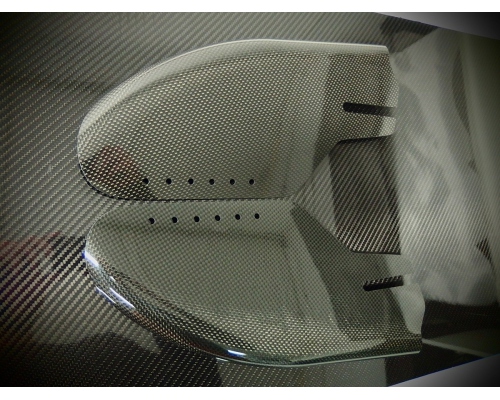

Automotive industry:

- Diffusers;

- Lip spoilers;

- Splitters;

- Motorcycle silencer muffler tips.

Water sports:

- Sailing boat equipment;

- Diving backplates;

- Diving fins.

Military:

- Ballistic protection (Aramid/Kevlar);

- NATO vehicle tables and components;

- UAVs and Drones;

- Battery boxes/cases.

Health care and rehabilitation:

- Carbon fiber side guards (fenders) for wheelchairs, ultra low weight carbon sheets;

- Foot orthoses, back orthoses;

- X-ray scanner table tops penetrated by x-ray radiation.

Industry:

- Light weight automated machine arms and other parts;

- Industry machine casings;

- 3D scanner parts of outstanding low thermal expansion;

- Carbon fiber sheets

Fashion, design:

- Laptop cases;

- Wallets;

- Premium product cases;

- Interior design elements;

- Furniture fronts (carbon fiber veneers);

- Loud speakers "high-end" fronts (carbon fiber veneers);

- Business cards.

And more more carbon fiber composites (carbon fiber molding).