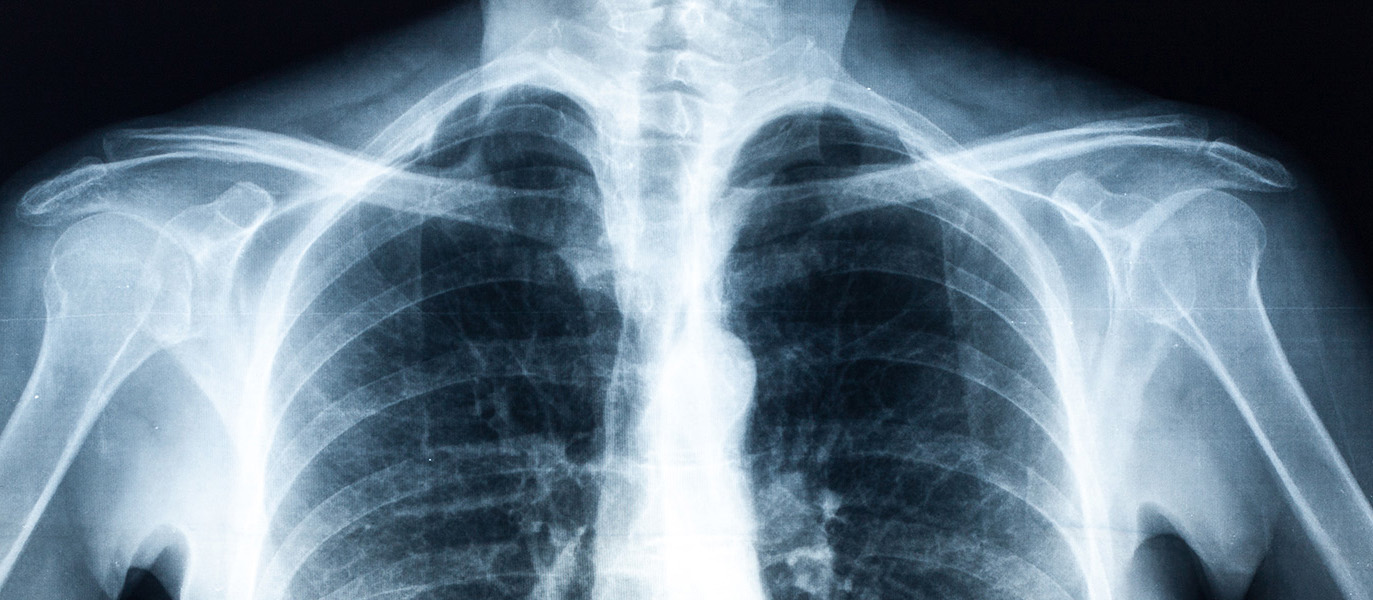

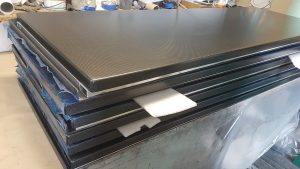

Carbon fiber X-ray radiolucency tables and top boards for medical market

X-rays and carbon fiber

Carbon fiber composites offer unique properties including high rigidity and low weight, almost zero thermal expansion and radiolucency.

The last one is very useful for medical devices and other x-ray systems. Carbon fiber composites do not block X-rays, permit short scanning duration and precise results, and prevent excessive exposure to X-ray radiation. This property, combined with high rigidity, makes carbon fiber composites the perfect material for manufacturing X-ray system table tops e.g. intended for chest, bone and human body X-ray scanning.

Carbon fiber composites are used for manufacture of X-ray system table tops and tables used for animal and human body scanning.

Use of conventional materials for X-ray devices

X-ray tables are typically up to 180-250 cm long and 50-90 cm wide. X-ray tables must offer rigidity appropriate for patient body mass that very often weighs over 100 kg and in extreme cases up to 200 kg.

The table should also be thin to enable penetration of X-rays through the human body during scanning. Thinner table tops result in more precise scanning.

Although metals meet expectations regarding mechanical properties – steel or aluminum possess relatively high rigidity – yet they are radiopaque which means that they block X-rays and distort scanning. The higher the density of material and higher atomic number, the more X ray radiation will be blocked during scanning.

Steel offers density of 7.9 gram per cm3 and has atomic number 26.

Aluminum has density of 2.7 gram per cm3 and has atomic number 13.

By comparison, carbon fiber composite offers density of 1.55 gram per cm3 and has atomic number 6.

It is interesting that X-ray rooms are lined with metal (lead) panels that prevent the escape of X-radiation outside the room. Lead possesses very high density (11.3 gram per cm3) and exceptionally high atomic number of 82.

On the other hand plastic (e.g. plexiglass /acrylic) or wood – has moderate radiolucency of X-rays and also presents disadvantages such as poor stiffness. The plastic table will be subjected to bending and has a thick structure which has a negative impact on scanning duration and quality.

Use of carbon fiber to manufacture top boards and tables for X-ray devices

Carbon fiber composites feature:

- Rigidity and low weight that are crucial for manufacture of high performance X-ray devices/systems

- Radiolucency (they do not block X-rays)

- The desirable properties of metals and plastic without their disadvantages

- Resistance to corrosion

Carbon composite top boards and tables absorb 5 times less X-ray radiation than acrylic top boards, and half as much as a wooden board.

Consequently this material ensures high quality scanning and prevents excessive exposure to X-ray radiation, which is of crucial significance when considering impact on the health of patients and personnel. Therefore X-ray carbon fiber tables and carbon fiber arm boards are becoming more and more popular in hospitals and private clinics.

An operator using an X-ray scanning system fitted with carbon fiber composite top boards can obtain high quality scans very quickly compared with traditional systems.

Carbon fiber tables offer greater rigidity than plastic tables with reduced table thickness. Plastic table components have to be much thicker to match the rigidity that carbon fiber tables offer.

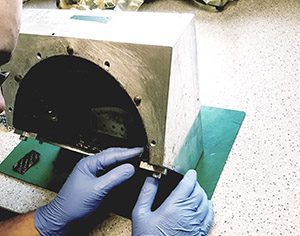

Carbon fiber used to manufacture X-ray systems for military and police

In addition to medical equipment, a special property of radiolucency is widely used in military systems and equipment used by police. Carbon fiber is widely used for the manufacture of portable equipment used for scanning of left luggage at airports or any suspected object, such as car doors, for detecting explosives or drugs.

Manufacturer of carbon fiber composites for X-ray devices

Dexcraft manufactures and supplies carbon fiber tables for X-ray scanning systems, as well as casings for portable scanning systems intended for military purposes and equipment used by police.

We supply tables made from both solid carbon fiber and foam core models (sandwich construction).

To find out more please contact us at:

www.dexcraft.com, info@dexcraft.com, Phone: +48 797-775-826, + 48 505-555-524

Tags: Carbon Fiber Armboards, carbon fiber x-ray table, x-ray translucency material, x-ray translucency, fully radio translucent imaging operation table, carbon fiber tables for x-ray, carbon fiber cases for x-ray mobile devices, carbon fiber top boards for medical x-ray

Very valuable information about how x-rays penetrate carbon fiber. No many articles available explain this as clear.