Carbon Fiber Composites

Carbon fiber composites have many unique properties including extreme strength, light weight, original and prestigious design. Yet this material has many secrets – as far back as 40 years ago it was used only by military research centers and NASA.

What are carbon’s fiber composite secrets? What are its properties? Why is this material so highly regarded by designers of racing cars?

HISTORY OF CARBON FIBER COMPOSITES

The beginnings of carbon fiber date back to 1963. At this time the carbon fiber technology was extremely costly and was reserved only for military aviation and spacecraft construction. Lightweight elements of carbon fiber gradually replaced heavy metal components, which enabled faster acceleration and higher speeds.

At the end of 70s, Formula 1 teams were extremely interested in Carbon fiber composites. This material was first used by McLaren, who in 1981 constructed the MP4/1 – pioneer Formula 1 racing car made from Carbon (total weight of 585 kg/1289 lbs). Nowadays, every Formula 1 car is made from carbon fiber.

McLaren was also the pioneer of using carbon fiber to manufacture motor cars for use on public roads. In 1994 McLaren unveiled a racing car named in honor of Formula 1 – McLaren F1 (not to be confused with a Formula 1 racing car). The body of this car weighed about 100 kg/220 lbs. It was the fastest motor car until 2005.

Then the record established by McLaren F1 (388.5 kph/241 mph) was broken by another car made from carbon fiber composites – namely the Koenigsegg CCR. Eventually the CCXR model reached 395 kph/245 mph.

Gradually, carbon became affordable for manufacturers of different composites. In time, carbon fiber was everywhere in production of racing car and motorcycle bodies, bicycle frames, skis, tennis rackets, fishing rods, yacht masts, carbon fiber sheets etc..

WHAT IS THE STRUCTURE OF CARBON FIBER COMPOSITES?

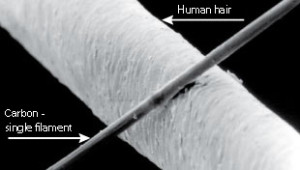

The term carbon fiber most often relates to textiles made from woven fibers. Each fiber contains from 3 thousand (3k fabric) up to 12 thousand filaments (12k fabric). The thickness of carbon fiber single filament is 1/10 of human hair (0.005-0.010 mm).

To find out more about the complex structure of fiber and uniform filaments, watch the movie that zooms in the bicycle frame to show atoms that make up the carbon fiber.

TYPES OF CARBON FIBER FABRICS

Carbon fabrics feature different weaves that determine the appearance and strength of the product, as well as the manufacturing process.

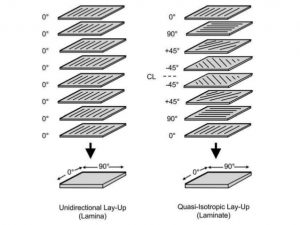

One-way patterned i fabric features very good strength along the filaments, and reduced strength crosswise. These fabrics provide the perfect solution when a section is exposed to pressure along one plane (along the filament). To maintain high tensile strength in any plain requires a structure composed of several fabrics at different angles (e.g. 0, +45, +90, -45) - quasi-isotropic carbon fiber composite. One-way patterned fabrics do not offer an attractive appearance, and consequently most often are used for the underside layers of composites.

Twill – filaments woven at a 90 degree angle. This pattern provides uniform strength in different directions and adds an attractive appearance to the composite.

Plain fabric 1/1 – product made from 1/1 fabric features different patterns of carbon filaments compared with the product made from 2/2 fabric. Plain type fabric is used for plain shapes due to poor stretchability.

Unimpregnated carbon fabric is as flexible as plastic sheet. It requires resin impregnation (preferably with epoxy resin) to create a strong composite from carbon fiber. Usually the manufacturing process of carbon fiber element involves resin impregnation of fabric placed inside the mold (manually, with vacuum bag or infusion). It is assumed that the more carbon fiber is contained in the composite, the higher will be the ensuing strength. For example, a carbon composite section weighing 500g where 60% of the weight (300g) is composed of fabric and 40% (200 g) resin will demonstrate higher strength compared with a carbon composite of 500 g weight where 40% (200 g) is fabric and 60% (300 g) is resin.

Pre-preg is the “top class” fabric which undergoes impregnation with resin during manufacture, along with hardener that features slow binding. Pre-pregs are stored in a refrigerator to prevent hardening. An advantage of pre-preg is a precisely defined and very beneficial ratio of fabric weight (reinforcement) and resin. The disadvantage is the price of material and high costs of the manufacturing process.

Pre-peg type carbon fiber is used, amongst other things, in F1 and other racing cars like Paggani or Koenigsegg.

Find out more about prepreg carbon fiber (pre-peg) used by Koenigsegg for car manufacture:

PROPERTIES OF CARBON FIBER COMPOSITES

Carbon fiber composites offer unique properties that make this material stand out from other structural materials. Below you will find a summary of the main properties of carbon fiber composites:

Low density and low mass

Carbon fiber composites have low density and low mass. Carbon fiber composites have a density of 1.55 g/cm3 (epoxy resin 30%, carbon fiber 70%), that in the case of aluminum is 2.7g/cm3 and 4.5 g/cm3 for titanium or 7.9 g/cm3 for steel.

For example, let’s consider a 1x1 meter sheet that is 1 cm (10mm) thick.

This sheet will have the following mass depending on the material:

- 15.5 kg in the case of carbon fiber composite

- 27 kg for aluminum

- 45 kg for titanium

- 79 kg for steel

In other words – a carbon fiber composite will be 42% lighter than an aluminum one, 3 times lighter than one made from titanium and 5 times lighter than a steel one.

High stiffness

Carbon fiber composites have high rigidity. Carbon fiber composites manufactured using pre-preg technology with standard fabrics and 0/90 weave offer stiffness of 90.5 GPa (Young’s modulus), whereas aluminum offers 69 GPa. What is more, carbon fiber composite is 42% lighter than an aluminum one of the same thickness. The above calculation refers to components of the same thickness.

When weight is the priority, and a design engineer may not exceed weight limit of 1kg, then carbon fiber composites made from standard fabrics (twill) will offer stiffness 2 times higher than aluminum and steel and almost 4-5 times higher stiffness in case on unidirectional fabric.

It is possible thanks to the high stiffness of carbon fiber composites and lower density. Consequently the designed product wall may be thicker with the same weight. For example in the case of a steel element 1.5mm thick, the same part made from aluminum will have thickness of 4mm and one made from carbon fiber will be 7mm.

To put it simply, material thickness increased x 2 provides rigidity of 23 – so about 8 times more. This provides many opportunities with regard to weight reduction by using carbon fiber.

Almost no thermal expansion

Carbon fiber composites have a very low coefficient of thermal expansion (CTE).

Carbon fiber linear coefficient of thermal expansion at 20oC is 2 (10−6°C−1).

Comparing the linear coefficient of thermal expansion with other structural materials at 20oC is as follows:

- 8 (10−6°C−1) in the case of titanium

- 11 (10−6°C−1) in the case of steel

- 17 (10−6°C−1) in the case of stainless steel

- 23 (10−6°C−1) in the case of aluminum

In other words, carbon fiber composites offers thermal expansion 4 times lower than titanium, 5.5 times lower than steel, 8.5 times lower than stainless steel and 11.5 lower than aluminum.

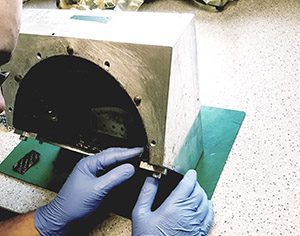

Compatibility with X-rays

Carbon fiber composites are widely used in the health care industry as it is a radiolucent material which does not block X-rays, ensures short scan duration and precise results of scanning. Therefore it is used for the manufacture of X-ray systems (scanner table tops). Please read more about carbon fiber and X-ray's.

Moderate resistance to temperature

Most carbon fiber composites offer resistance to temperature of 70-120oC. To ensure long term resistance to temperature up to 150-250oC some specially designed resins are required and carbon fiber composite needs to undergo curing at high temperature for many hours. This is a disadvantage of carbon fiber composites, as compared to metals that have resistance to high temperature.

In the case of carbon fiber composites, some costly materials are required (for instance phenolic prepregs) to offer resistance to high temperatures as well as high temp curing of the composite.

Although metals have a high melting point, in practice it is assumed that metals change their properties at a temperature of ~300 oC in the case of aluminum, 750 oC in the case of steel and 860 oC in the case of titanium. A design engineer can obtain the material that offers all required properties that give metals an advantage - and any further treatment is not required in the production process.

Fiber orientation – no isotropic material

Unlike metals, carbon fiber composites are anisotropic materials.

Consequently composite properties such as stiffness depend on fiber orientation. In the case of metals, properties are always the same no matter what the orientation and these materials are called iso-tropic. This is a significant difference between carbon fiber composites and metals. Carbon fiber composites are similar to wood, whose strength and stiffness depend on grain and ring pattern.

At carbon fiber elements production time, a decision is taken regarding the orientation of carbon fibers and type of fabric. There are, for example, unidirectional fabrics (UD), bidirectional ones (e.g. . plain or twill) as well as fabrics made from some differently orientated UD fabrics– e.g. biaxial, triaxial. This production process enables an optimal composite, namely to ensure more fabrics at locations exposed to high load and reduced fabrics in places where the load is limited.

Moreover, in addition to the control over quantity of fabrics and thickness of element, this process also ensures control over fabric orientation depending on loading in practice. Therefore you can significantly reduce the weight of an element compared to one made from metal. However, this requires some know-how and experience from the design engineers.

If, for the given element, the strength is required in any specific direction, carbon fabric shall be uniformly orientated at 0, -45, + 45, 90 degrees, to provide for quasi-izotropic layout similar to that found in metals.

CARBON FIBER COMPOSITES – MANUFACTURING METHODS

Depending on production volume, element design, size and required properties, as well as aesthetics, there are several methods available for the production of carbon fiber composites.

Manual laminating

This is a very simple method for carbon fiber composite production that is frequently used for manufacture of glass fiber composites. This technology is used for details of simple design without any specific aesthetic and structural requirements, produced manually using a roller and brush. Some disadvantages related to this method include poor repeatability, air voids inside the carbon composite and weave damage. This production method does not require costly equipment such as autoclaves or heat presses.

Vacuum bagging

The technology that uses a vacuum bag has been developed from a basis of manual laminating. The initial steps are identical to manual laminating, where a resin is applied manually with a roller or brush and then layers of carbon fiber fabrics are positioned. The difference relates to use of the vacuum bag at the final phase. As the name suggests, the vacuum bag provides sealing around the mold to extract air using the vacuum pump. The vacuum generated ensures adhesion of carbon fiber fabrics to the surface and pressure against the mold.

In spite of some theoretical advantages related to consolidated laminate, production with the vacuum bag does not prevent air voids that are very common in this method, therefore it is used occasionally for production of carbon fiber parts and details. If high quality is not required, manual production is used, whereas if high quality is priority then resin infusion, prepreg or hot-press technology is preferred.

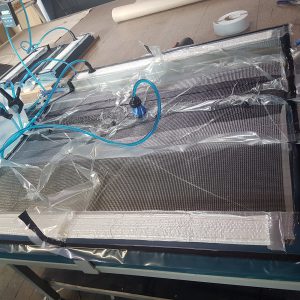

Resin infusion

Unlike previous methods, resin infusion technology relates to placement of dry fabrics e.g. 5 layers of 200 g weight. These fabrics are sprayed with special adhesive to ensure a perfect fit to the mold and weave. Then special netting is positioned to ensure proper distribution of resin. The whole is sealed with film and butyl tape. From one side, the vacuum pump is connected which initially sucks in air using the vacuum while the vacuum bag ensures fabrics are pressed against the mold. Next, from the other side, the valve will be opened on the supply duct from the resin tank. Thanks to the vacuum, the resin is supplied automatically through the netting and ducts placed previously to ensure impregnation of the dry carbon fiber fabrics.

RTM

This method is used for large volume production of carbon fiber composites that are usually finally painted with color (not clearcoat). Usually steel or aluminum molds are used, male and female. Firstly, dry fabrics are placed inside the mold. Then the molds are forced together and sealing is provided around and between the molds. With this technology, resin injection follows under high pressure (10-20 bar). The process of impregnation and hardening takes 30-60 minutes. High Pressure RTM follows at pressure up to 100-120 bar and it the whole production process takes just 10 minutes.

The main advantage of this method is a smooth surface (both sides) and relatively short production cycle. Whereas disadvantages include high costs of process implementation and production of carbon fiber composites intended for painting. Actually this technique does not ensure perfect placement of carbon visual fabrics and neither does it highlight the structure of carbon fiber when a clear top coat is applied only.

This method has been used for large volume production by the Dodge Company during the manufacture of Viper (2005). At present, some parts are manufactured using this technology, as well as the body of BMW i3 and BMW i8 or roof of BMW M3 and M6 racing cars.

RTM Light

A difference between RTM and Light RTM relates mainly to the pressure. In the case of the first method, resin infusion pressure is 20-120 bar whereas with Light RTM it is only 1.2 bar and the whole process uses negative pressure. This process enables the design of a countermold of low weight, mostly composite one hence the name”Light” RTM. Resin infusion pressure is ca. 1.2 bar and negative pressure is 0.7 bar.

Resin infusion follows at one side under low negative pressure of 1.2 bar and extraction follows from other side (as in case of Resin Infusion) at negative pressure of 0.7 bar. The differential pressure results in impregnation of the fabrics inside. This method is rarely used for production of carbon fiber composites as it offers poor quality and aesthetics compared with RTM.

Prepreg autoclave composites

The prepreg method with autoclave is widely used for production of carbon composites for F1 racing cars, monoblocks, diffusers, front wings as well as spoilers. This technology ensures the highest quality and aesthetic appearance of carbon fiber composites but it comes with high costs due to use of expensive equipment – autoclaves - and moderate production cycle (compared with hot-press (HP) or RTM.

An autoclave is a device that generates high pressure ~ 8 bar and high temperature ~120-150°C at the same time. This method includes use of prepregs, namely carbon fabrics, which have been pre-impregnated with a resin. Consequently the material– resin preimpregnated carbon fiber fabrics - are supplied as 30-50m rolls and are kept in a refrigerator to prevent accidental hardening. Hardening of carbon fabrics preimpregnated with resin follows at high temperature >90°C, and consequently their service life after removed from the refrigerator is 20-40 days at ambient temperature depending on the type of material. In practice, after removal of the prepreg roll from the refrigerator, you need to wait 2-3 hours so that the material is soft and cutting is possible. Next, after unfolding, the material is placed on the plotter and cutting follows according to production needs. Then the remainder of the roll is replaced in the refrigerator. The material may be stored in the refrigerator for 4-8 months.

Prepregs are similar to sticky oilcloth. This material easily sticks to mold walls and consequently it is possible to form complicated shapes. After inserting layers of prepreg, the molds are sealed with film and butyl tape. Next, pressing follows against the mold using a vacuum that removes the air from the product. Later the mold, including the sealed product, is placed inside the autoclave that generates pressure up to 8 bar to press the carbon prepregs against the mold walls to remove any air and ensure structure consolidation.

Finally, after hardening usually for 1-2 hours at 120 degrees, you can depressurize the autoclave, switch off the heaters and remove the finished carbon fiber composite.

Advantages of manufacturing prepreg autoclaved carbon fiber composites:

- Possible hardening of any quantity during one production cycle (e.g. 50 identically formed details).

- Highest aesthetical appearance of composite – absence of air voids and fabric weave damage.

- Possible production of details with complex shapes and use of combined, multi-part molds.

Disadvantages of manufacturing prepreg autoclaved carbon fiber composites:

- High costs of equipment – autoclave.

- Modest time consuming process (shorter than infusion resin and longer than hot-press).

- Requires molds that are resistant to high temperatures – most often costly carbon prepeg molds or aluminum ones fabricated by milling.

Hot-press / Thermoforming

This method is usually used for large volume production of products and parts of simple design and usually small dimensions.

With this method, as in case of autoclave, carbon prepregs are used. The difference relates to the press that is used to ensure forcing the prepreg layers against the mold instead of air pressure as in case of autoclave. Both molds are pressed with the heating press, which provides rapid heating. Hot-press forming most often follows, with prepregs of short hardening time of only 5-10 minutes.

Advantages of carbon fiber composite production with hot-press forming:

- High up to ~70% carbon fiber content in composite, similar to the autoclave method.

- Resistance to high temperature.

- Short production cycle.

Disadvantages of carbon fiber composite production with hot-press forming:

- High costs of production implementation.

- Difficult to make elements having so-called negative angles

Bladder molding

Technology for bladder molding uses carbon prepregs as in the case of production of carbon composite using hot-press and autoclave.

- Prepregs are placed inside both molds (male and female) and around the bladder.

- Bladder is placed inside the molds and mold is closed and locked.

- Pumping follows inside the bladder to ensure pressure required to obtain desired quality of surface. The generated pressure e.g. 4 bars pushes the prepregs against mold walls to remove any air and ensure carbon composite structure consolidation.

- Mold heating – inside the press, oven or autoclave.

- Upon composite hardening, pressure is reduced. After disassembly the bladder is removed. A bladder is a multi-use part.

When bladder molding is used?

This technology is used for production of complex long components of small diameter e.g. a bicycle frame.

CARBON FIBER COMPOSITES - ADVANTAGES AND DISADVANTAGES

Carbon fiber composites offer both advantages and disadvantages.

Advantages of carbon fiber composites:

- Carbon fiber composites have low weight – ca. 40-50% lighter than aluminum and stiffness improved 4-5 times compared to steel and aluminum of the same weight. This material is widely used for production of racing car body parts (F1), ultra light bicycles, fishing rods, automated machine parts, drones or military products.

Low weight of carbon fiber composites contributes to energy savings as lighter vehicles consume less fuel. It is assumed that vehicle weight reduced by 10% results in fuel consumption reduction by 6-8%. Therefore electric driven vehicles such as BMW i3 or i8 have a carbon fiber chassis that increases driving range. - Carbon fiber composites offers unique properties including very low thermal expansion. For example carbon fiber composite has thermal expansion 5.5 times lower than steel, 8.5 times lower than stainless steel and 11.5 lower than aluminum. Therefore thanks to almost zero thermal expansion, carbon fiber composites are used in optics – for production of 3D scanners and for military purposes e.g. manufacture of high-precision satellite disks.

- Another advantage of carbon fiber composites relates to compatibility with X-ray radiation. Carbon fiber composites do not block X-rays and therefore they are widely used for production of X-ray scanning systems.

- Because of its unique and original aesthetic appearance, carbon fiber composites are used in the automotive industry and for design purposes. Actually it is a material associated with premium class products, as it is used by racing car manufacturers, as well as suppliers of surfing boards, kayaks, crash helmets, loudspeakers, coffee machines and many other premium class products.

Disadvantages of carbon fiber composites:

- The biggest disadvantage of carbon fiber composites relates to its production costs. Carbon fiber composites are mostly manufactured by manual placement of a few layers of carbon fabric. The whole process takes time and generates some costs. Additional materials used are costly, such as carbon fabrics, resin, pre-pregs. A square meter of carbon pre-preg costs ca. 30-50 EUR and, for instance, to manufacture composite 2mm thick, 4-5 layers are required. Carbon fiber composites treatment followed by 3 or 5-axis CNC carbon fiber machining and usually it is covered with a few topcoat layers, which results in high production costs.

When it comes to advanced production such as manufacturing carbon fiber composites with autoclave, expensive equipment is required – e.g. autoclaves costs ca. USD ~500,000.

Consequently the final product costs a few times more than one made from aluminum, for example. - Another disadvantage relates to some limitations at the design phase. Not every detail that can be achieved by aluminum milling may be manufactured using carbon fiber, and some details need to be adapted in a specific manner.

- Although carbon fiber offers many advantages regarding its properties note that carbon composite offers poor/modest resistance to impacts – that makes it fragile compared to steel or aluminum material. Therefore details or parts exposed to impacts are made from carbon-glass fiber composites, carbon-aramide composites, carbon composites including aluminum honeycomb or a combination of these.

- Carbon fiber is a material that conducts electric current, although less than metals.

- Metal elements included inside carbon fiber (e.g. threaded bushing) must be isolated with resin or adhesive to provide anti-corrosion protection.

- Other disadvantages relate to repair of carbon fiber composites – .e.g. a broken bicycle frame. These parts are beyond repair often or repair is difficult and costly.

- Unlike metal parts, carbon fiber composites are combustible which means that they may ignite and catch fire when exposed to naked flames for a period of time.

9 SECRETS ABOUT CARBON FIBER COMPOSITES:

- Carbon composite offers strength up to 5 times greater than steel (weight for weight).

- Carbon fiber used for manufacture of F1 and other racing cars (called “pre-pregs”) costs as much as USD $60/m2.

- Carbon fiber composite offers modest conductivity (less than metals).

- Carbon is black that provides a unique pattern. Composites in any other color may be fake carbon fiber - coloured glass fiber or kevlar.

- Carbon fiber is a very rigid material, with Young modulus of 230 Gpa (Toray T300, alongside fiber). The higher the Young modulus, the greater the rigidity of the material. Carbon fiber of high modulus (improved strength) typically has a Young modulus alongside fiber of 500-880 GPa (example of 880 GPa fiber - Granoc XN 90 Nippon). For comparison, steel typically has a Young modulus of about 200 GPa.

- Carbon composite demonstrates low thermal expansion– it expands at high temperature and contracts at low temperature much less so than materials like steel and aluminum.

- Carbon is more resistant to material fatigue– elements made from carbon fiber offer more strength during heavy duty operation.

- Carbon, like other composites, enables you to determine the strength of any area of an element – in any direction. For example, a bicycle frame made from carbon fiber will have many layers of fabric at locations exposed to high load, whereas there will be a minimum number of layers at places that do not transfer load. Such design optimizes and reduces the weight of the composite.

- Carbon fiber has some weaknesses also– e.g. average impact strength. In case of elements exposed to impacts (e.g. panels under the engine of WRC cars), aramide fiber is often used (called Kevlar).

CARBON FIBER PRODUCT SUPPLIER

Our Company is a supplier of carbon fiber composites

We supply series of carbon fiber products. Depending on the strength required, the manufacturing process can include prepreg technology, resin infusion, vacuum bag or manual laminating.

Location: Poland (Europe), Worldwide shipping.

Contact us: Dexcraft Composites, www.dexcraft.com, info@dexcraft.com, tel. +48 797-775-826, +48 505-555-524

Leave a Reply Cancel Reply

Search

Who we are?

We have more than 10 years experience in providing supplies of complex carbon fiber composites.

Visit our website: www.dexcraft.com

Thank you for all comprehensive information about carbon fiber composites. I have shared it on message board.